As a miserable, cold rain fell outside, and Team USA struggled against Slovakia in Mens Olympic Hockey, I put the first of two overall coats of epoxy on the interior hull. Even though the strakes had been previously coated or fiberglassed, this overall coat of unthickened epoxy served to seal the inter-strake joints, as well as to fill the weave of the fiberglass on the bottom panels. But first, I spent some time to give a final sanding to the stitch holes that I had previously plugged. This involved sanding the plugged holes, and also the edge of the fiberglass, which although carefully trimmed, was a little ragged in spots. After the prep sanding, I then had to spend time vacuuming and wiping down the surfaces which had become extremely dusty. (Which reminds me, can anyone recommend a good shop vac?) After the cleanup, I applied a coat of epoxy to the entire hull interior, giving special attention to the strake joints. I found that placing the foam roller lengthwise along the joint and pressing would squeeze some epoxy into the joint. Then rolling gently over it would give a smooth finish.

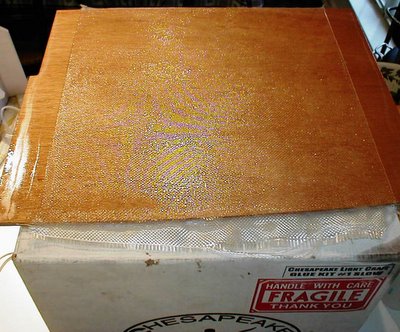

As a miserable, cold rain fell outside, and Team USA struggled against Slovakia in Mens Olympic Hockey, I put the first of two overall coats of epoxy on the interior hull. Even though the strakes had been previously coated or fiberglassed, this overall coat of unthickened epoxy served to seal the inter-strake joints, as well as to fill the weave of the fiberglass on the bottom panels. But first, I spent some time to give a final sanding to the stitch holes that I had previously plugged. This involved sanding the plugged holes, and also the edge of the fiberglass, which although carefully trimmed, was a little ragged in spots. After the prep sanding, I then had to spend time vacuuming and wiping down the surfaces which had become extremely dusty. (Which reminds me, can anyone recommend a good shop vac?) After the cleanup, I applied a coat of epoxy to the entire hull interior, giving special attention to the strake joints. I found that placing the foam roller lengthwise along the joint and pressing would squeeze some epoxy into the joint. Then rolling gently over it would give a smooth finish.I also glassed the interior surfaces of the daggerboard trunk. This was the first modification to the build instructions that I have made; it was suggested to me that this would be a good use of fiberglass cloth scraps that I have accumulated. So I applied the cloth and saturated with epoxy, then I quickly trimmed the edges using a straight edge, and removed the glass cloth where the trunk spacers will be. With a putty knife, I scraped the epoxy from the spacer surfaces, so as to have a clean mating surface. When the epoxy gels, Ill trim the cloth overhang. Total hours 50.75.

0 komentar:

Posting Komentar